SOP - Bimetallic Lugs/Copper & Aluminium Cable Lugs Crimping Process

1. Check that tooling is Clean and not worn. If necessary Replace the worn tool if found any damage.

2. Install & Fit the appropriate Crimping dies into the Tooling.

3. Put Bimetallic Lugs into the tooling so that it can be checked the proper fitment of tooling as per Lugs OD.

4. Ensure the Cable Strip length as per the Lugs Barrel length which is to be done by checking the barrel length.

5. Insert the conductor fully into the Cable Lug.

6. Observing the Crimping direction, Crimp the cable lug using the appropriate tools as per the direction mentioned.

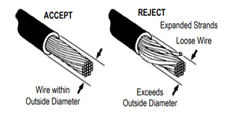

The crimping direction for cable lug is indicated in the diagram below attached

7. The crimping press load will be define as per the tooling available at site for crimping.

The crimping process will continue till both upper and lower die envil does not contact each other surface.

8. The number of crimp will depend upon the size of barrel.

9. Remove the crimped Lugs from the crimping tool and check it visually if any crack found on it.

10. Remove excess compound emerging from Cable Lugs after crimping done in complete barrel length.